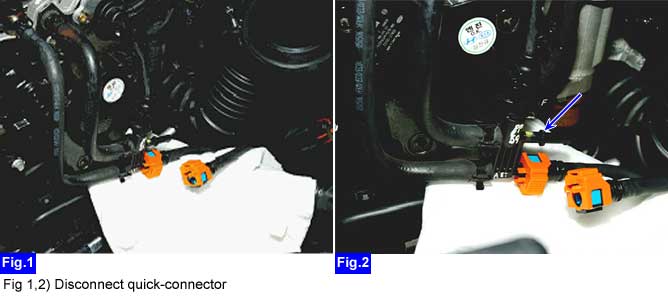

Disconnect fuel supply hose quick-connector from function block.

- Make sure of fuel leak after disconnecting fuel hose quick-connector and an inrush of foreign substances.

Make sure of fuel leak when fuel pressure gauge is installed for low pressure fuel system. Make sure of fuel leak after reassembling fuel hose quick-connector.

If fuel pressure of low pressure fuel system is low and engine stalls (vehicle is being stopped) although fuel pump is operated and fuel is supplied, Inspect hose leak of fuel pump in the fuel tank.

IG KEY "OFF", ENGINE "OFF"

Disconnect air cleaner assembly and MAFS connector.

Disconnect fuel supply hose quick-connector from function block.

- Make sure of fuel leak after disconnecting fuel hose quick-connector and an inrush of foreign substances.

Install pressure gauge of low pressure fuel between the fuel hose quick-connectors.

- Make sure of using low pressure gauge(CRT-1051), gauge connection tube(CRT-1052), connection adapter(CRT-1053).

"CRT-1000 Tester Composition" of "Details Inspection(Equipment Setting)" reference

IG KEY "ON", ENGINE "ON"

- Fuel pressure will be 0 bar after rising 3.5 bar when low pressure fuel pump is operated approx. 2 seconds at IG KEY "ON".

- Make sure of fuel leak in the quick-connector at ENGINE "ON" after installing pressure gauge.

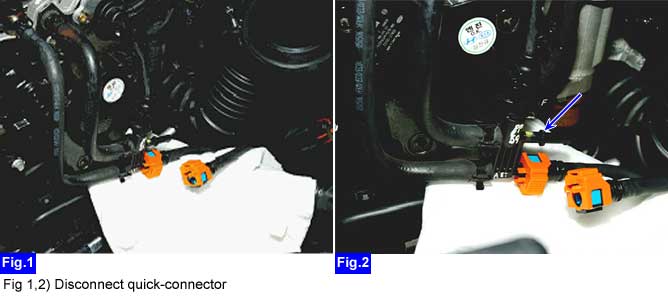

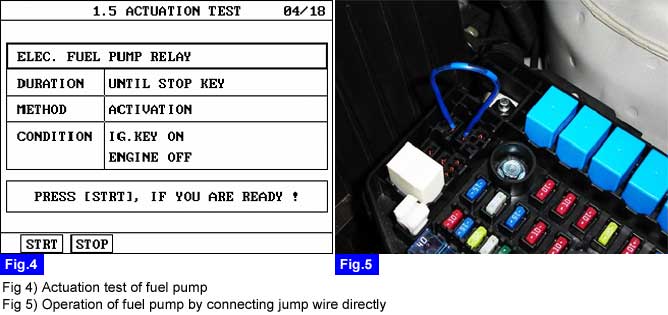

Operate the fuel pump by using actuation test on the scantool or connecting jump wire directly after remove the fuel pump relay on the engine compartment junction block.

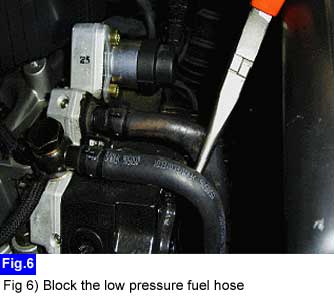

Block the low pressure fuel hose of the high pressure pump by using pliers.

- Make sure that fuel hose must not be torn.

Measure the low fuel pressure. (Pressure must be increased to relief pressure of the fuel pump.)

Specification : Approx. 7.0 ~ 7.5 bar at IG KEY "ON" (Pressure would be 0 bar within 1~2 seconds after IG KEY "OFF")

Case 1 : In case that fuel pressure is not increased relief pressure of the fuel pump.

If there is no leak, Inspect fuel hose damage, disconnection of the fuel pump in the fuel tank and block of the pump strainer.

Case 2 : In case that fuel pressure is higher than relief pressure (7.5 ~ 8.0 bar).

Replace the low pressure fuel pump. (Relief valve in the fuel pump is stuck.)