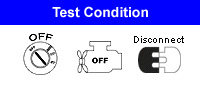

Check cylinder compression pressure.

1) Insert a compression gauge into the spark plug hole.

2) Fully open the throttle.

3) While cranking the engine, measure the compression pressure.

4) Repeat steps (a) through (c) for each cylinder.

Compression pressure Specification :

Standard : 1,176.79 kPa [12.0 kgf/㎠, 170.68 psi] (200 ∼ 250 rpm)

Minimum : 1,029.69 kPa [10.5 kgf/㎠, 149.34 psi]

Difference between each cylinder : 98.07 kPa [1.0 kgf/㎠, 14.22 psi] or less