Check MAFS

IG "OFF" and install a scantool

ENG "ON" and monitor "MAFS" data on the service data.

Monitor signal waveform at signal terminal of MAFS with scantool.

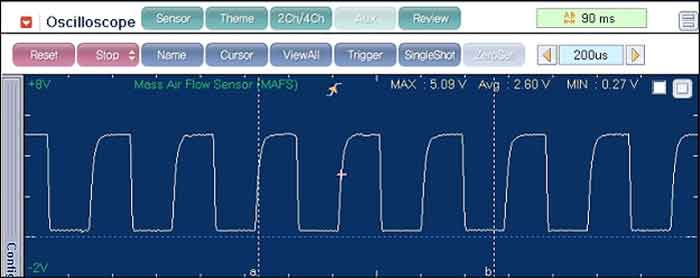

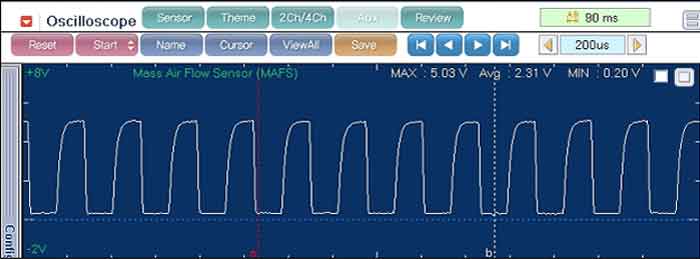

Specification : Signal waveform will be displayed as follows.

(Be aware that the signal of MAFS is not voltage display but frequency display.)

Fig.1. Idle

Fig.2. Acceleration

Are both service data and signalwave form dispayed correctly ?

YES

Clear DTC and Test-drive under enable conditions above-mentioned. After the test, If this DTC is set, go to "Inspection & Repair" procedure. If not, troubleshooting is completed.

NO

Substitute with a known - good MAFS and check for proper operation.

If the problem is corrected, replace MAFS and go to "Verification of Vehicle Repair" procedure.