Remove return hose clips.

- Clean the region of the return hose to prevent an inrush of foreign substances.

To remove high pressure fuel system, Never perform any work engine running or within 60 minutes after the engine stops. It is recommended to wear safety glasses. Ensure the absolute cleanliness to prevent an inrush of foreign substances in high pressure fuel system.

Through BACK LEAK test you can not know variation of Injection quantity and performance of injector. Inspect BACK LEAK when rail pressure could not be controlled by injector leak or Injector could not be controlled.

IG KEY "OFF", ENGINE "OFF"

Remove return hose clips.

- Clean the region of the return hose to prevent an inrush of foreign substances.

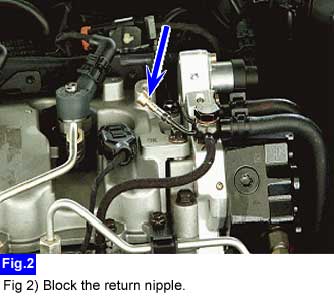

Block the return nipple by using injector return hose plug (CRT-1033) after disconnect fuel return hose.

"CRT-1000 Tester Composition" of "Details Inspection(Equipment Setting)" reference

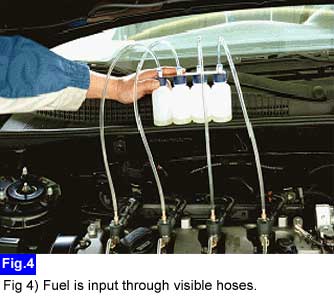

Install injector return hose adapter (CRT-1032), visible tube (CRT-1031) and flask & holder (CRT-1030) to return side of injectors.

Assemble return hose clips.

Monitor flasks (fuel is input through visible hoses.) after ENGINE "ON".

- Perform until 1/4 ~ 1/3 fuel is input in the least flask.

※ All conditions as below must be satisfied in the test.

- Test must be performed at idle.

- Inspect returning fuel quantity accelerating gradually the vehicle.(Monitor abnormal section increased suddenly.)

- Test must be performed at stall test also.(Monitor abnormal section increased suddenly or symptoms such as poor acceleration, engine stalling.)

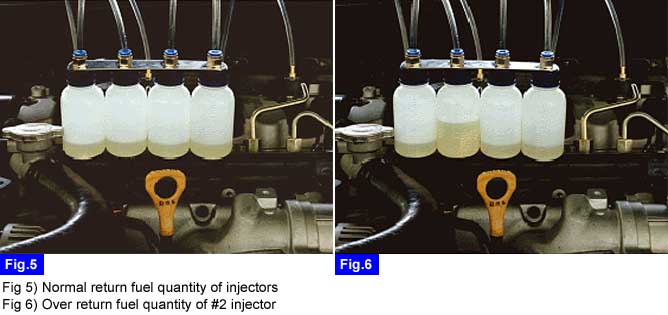

Case 1 : In case that there is no variation of return fuel quantity.

The cause of abnormal rail pressure control is not injector. (Return fuel quantity is normal.)

Case 2 : In case that the most flask has over twice as return fuel quantity as the least flask.

There is the leak in the most injector. Replace the injector if necessary.

Case 3 : In case that the most flask has over three times as return fuel quantity as the least flask.

DTC related with rail pressure would be displayed and engine stalls. (Rail pressure control is impossible)

Replace the injector if necessary.

Case 4 : In case that the return fuel quantity of the least flask is too small or nothing.

Inside of the injector is blocked.

Replace the injector.

If the Injector is replaced, IQA code input (Injector correction function) should be performed.

"Remove and Install the Injector" of "Details Inspection(Equipment Setting)" reference

"Injector IQA Code Input" of "Details Inspection(Equipment Setting)" reference