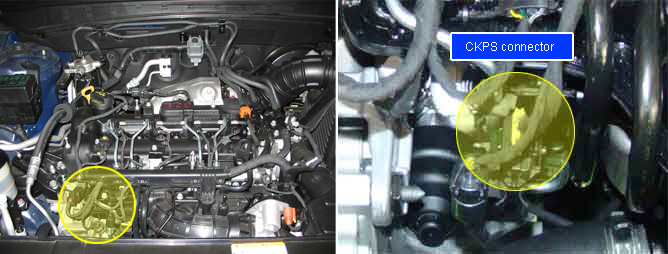

Crank Shaft Position Sensor (CKPS) is magnetic inductive type. Mounted on cylinder block, it senses magnetic encoder position of crank shaft. As magnetic encoder is divided with 58 teeth and 2 missing teeth (reference point), 1 tooth corresponds to 6 degree. CKPS which calculates RPM and crank angle is important to determine fuel injection quantity and injection timing with APS. Crank shaft position is closely related to engine starting.

DTC P0335 is set corresponding to the condition of ECM internal counter when CKPS signal does not generate while CMPS signal is outputted. This code is due to CKPS circuit or component failure. If CKPS signal is not inputted during driving, RPM is calculated based on CMPS signal.

Item | Detecting Condition | Possible Cause | ||

DTC Strategy |

•

Signal monitoring |

•

CKPS circuit

•

CKPS

•

Abnormal deformation of crank shaft magnetic encoder(tone wheel) | ||

Enable Conditions |

•

During accelerating and turning engine ON | |||

Threshold Value |

•

CMPS signal is outputted while CKPS signal does not generate. | |||

Diagnostic Time |

•

Corresponding to ECM internal counter condition. | |||

Fail Safe | Fuel cut | NO |

•

When CKPS failure, backup mode starts using only CMPS.

•

When CMPS failure, backup mode starts using only CKPS.

•

When Both CKPS and CMPS simultaneous failure, engine off | |

EGR Off | NO | |||

Fuel Limit | NO | |||

Check Lamp | ON | |||

Fig.1) This shows waveform of CKPS and CMPS simultaneously. The middle area indicates reference points of CKPS and CMPS.

☞ Injection sequence is determined based on Low and High signal of CMPS reference point as detecting cylinder position.