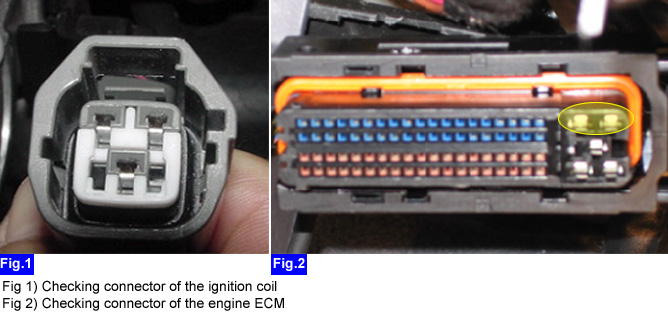

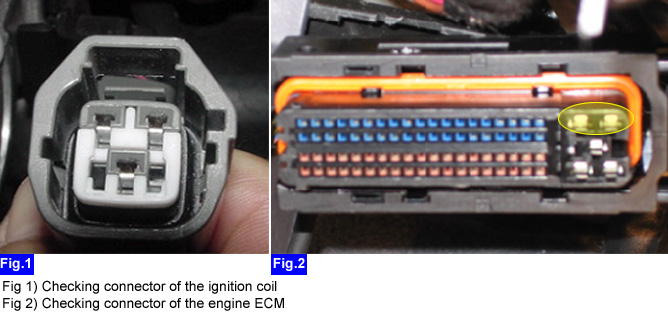

Check connection of the ECM connector after removing the ECM connector.

ECM includes power TR which controls ignition coils, According to CKP & CMP signals ECM controls the base of the power TR. The purpose of inspection is to check spark plugs, cables and pin connections of ignition coil harness.

IG "OFF"

Check connection of the ignition coil connector after removing the ignition coil connector.

Check connection of the ECM connector after removing the ECM connector.

Are connectors of the ignition coil and engine ECM normal?

YES

Go to "Ignition coil Inspection" procedure as below.

NO

Repair the pin of the connector or Replace the harness.

Engine "ON"

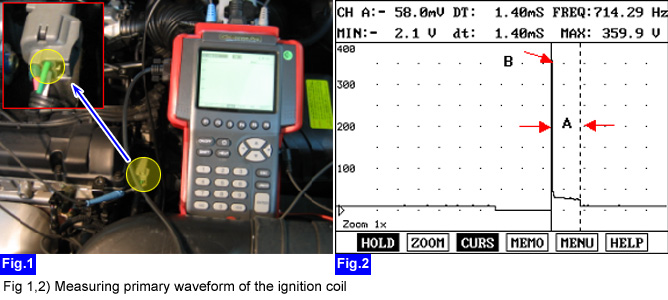

Connect a scantool and measure a primary waveform of the ignition. (Connect channel 1 probe of the scantool to #1,4 terminal of the ignition coil connector.)

Specification

A : 1.4~1.8mS, B : 360~380V

Is the primary waveform within specification?

YES

Ignition coil is OK.

NO

Go to "Spark plug and cable Inspection" procedure as below.

IG "OFF"

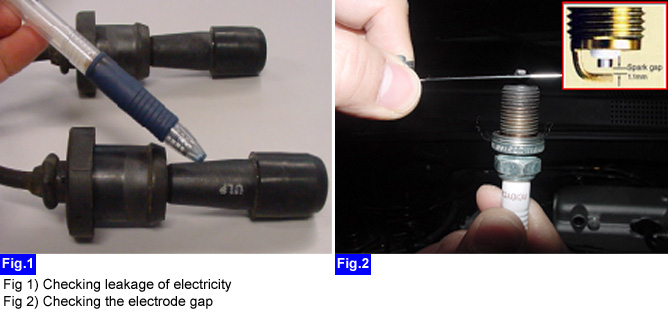

Check leakage of electricity after removing spark plug cables.

Check spark plug condition and electrode gap.

Specification : Electrode gab 0.0394 ~ 0.0433 in (1.0 ~ 1.1mm.), Tightening torque of the spark plug : 2.0 ~ 3.0 Kgf.m

Are spark plug and cable normal?

YES

Spark plug and cable are OK.

NO

Replace spark plug and cable.

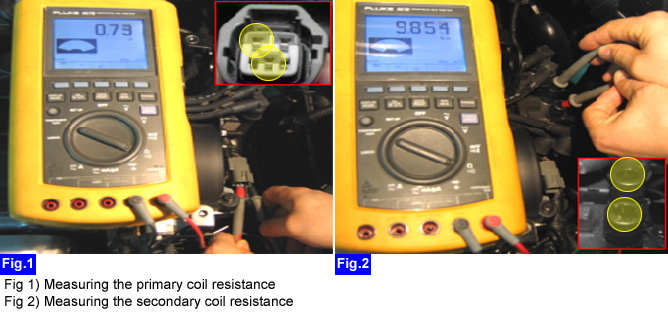

■ Measure resistance of Ignition coil

Primary coil resistance is measured between (+) terminals and (-) terminals.

Secondary coil resistance is measured between center terminals and center terminals.

Specification of Ignition Coil Resistance

Primary Coil : 0.58Ω±10%, Secondary Coil : 8.8㏀±15%