Clean the dust or foreign material out of high pressure fuel pipe and return hose fitting that is removed.

When removing the part of high pressure fuel system, wait for 30~60 seconds and check the pressure relief then proceed your job. And make sure to wear your protective glasses while you are working and keep cleaning your surroundings.

Foreign material may cause other problem in fuel system.

Stop the engine with IG key "OFF"

Wait for 30~60 seconds to let the inner pressure be disappeared.

Disconnect Battery (-) terminal.

Clean the dust or foreign material out of high pressure fuel pipe and return hose fitting that is removed.

Disconnect the connector of injector.

Remove the fixing clip of injector return hose.

Remove high pressure pipe and return hose of injector.

- When removing the high pressure pipe flaring nut of injector, unfasten the nut after holding the injector nipple.

- Attatch the dust cap (CRT-1035) on the injector side nipple so that foreign material not to come in.

- Keep the removed high pressure pipe on the clean zone so as not dust to come in.

Remove the injector fixing bolt.

- Slightly raise fixing knob and turn it 90 degree to the clockwise and raise it carefully.

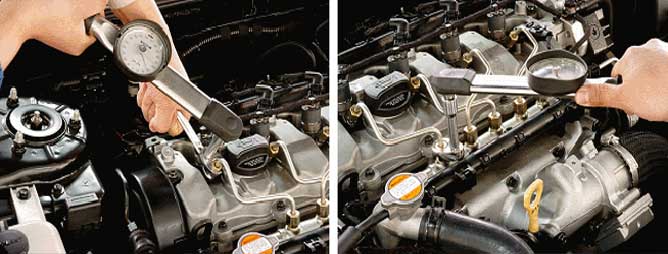

Using the T-40 tox wrench, unfasten injector fixing bolts located in inner side of removed plug.

- Do not remove bolt completely but unfasten it.

Slightly raise bolt and move it to the direction as shown in the picture

- Separate the injector and injector holder.

Remove injector from the engine. (Be care not to be impacted on the nozzle region)

Inspect the removed nozzle with eye and keep it in clean zone with nozzle protection cap.

Using the SST, clean dust on the region of the cylinder head and clean carbon.

Attatch new copper washer at the injector.

Install injector to the cylinder head with carefully not to be impacted on the nozzle region.

Move the injector holder to the injector side so that it can be fixed.

- Rotate injector slightly right and left and it can be positioned rightly.

Tighten the injector fixing bolt to the specified torque.

- If tightening bolt below specified torque, combustion pressure may be leaked and if tightening over torque it may change the injector characteristic of injector so that the injection quantity per operation be changed .

Specified torque : 2.5~2.9Kgf.m

Install the injector fixing bolt plug on injector.

- After installing the plug, raise fixing knob a little and turn it to 90 degree counterclockwise then tighten it.

Make sure foreign material not inflow, install the high pressure pipe, return hose and fixing clip.

- When installing the high pressure pipe, assemble it temporarily and then tighten completely.

- When fastening flaring nut of high pressure pipe on injector side, fasten the nut while holding the injector nipple.

- SST for installation and removal of high pressure pipe : injector side of flare nut:09314-27110, common rail side of flare nut : 09314-27120

Specified torque : 2.5~2.9Kgf.m

Connect the injector connecter.

Using scan tool, input the IQA data of injector which is replaced.

"Injector IQA inspection" of "Details Inspection(Equipment Setting)" reference

Turn the engine and check the engine condition and no fuel leakage.