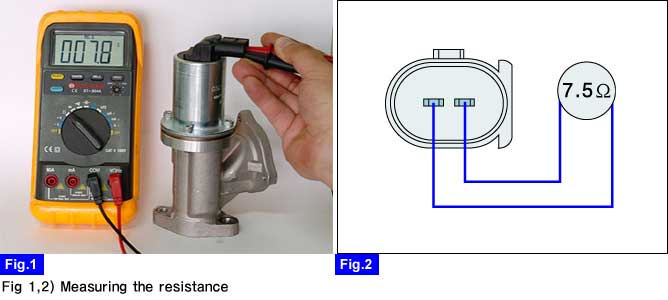

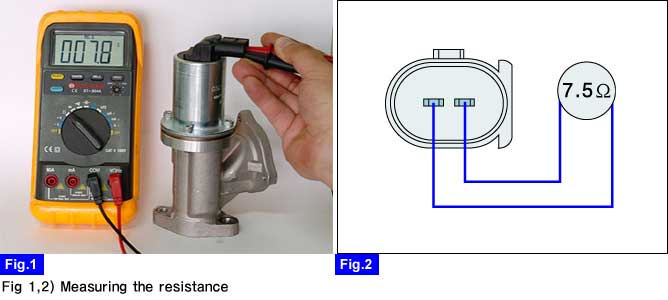

Measure the resistance between EGR solenoid valve terminal 1 and 2.

Specification : 7.5 Ω ± 10% ( 20℃ )

First of all check damage of terminals : Check terminals for contact resistance, corrosion and deformation. Before measuring resistance, you must calibrate(0Ω) the tester.

In case of abnormal "Air mass meter" data, Inspect the EGR solenoid valve component.

IG KEY "OFF", ENGINE "OFF"

Disconnect EGR solenoid valve connector.

You must calibrate (0Ω) the tester.

"Multitester Calibration" of "Details Inspection(Equipment Setting)" reference

Measure the resistance between EGR solenoid valve terminal 1 and 2.

Specification : 7.5 Ω ± 10% ( 20℃ )

Disconnect EGR solenoid valve connector.

Inspect the EGR solenoid valve after supplying battery voltage to EGR solenoid valve terminals.

- Inspect EGR solenoid valve operating sound, EGR solenoid valve operation (opening ↔ closing).

- Inspect carbon deposit in the EGR solenoid valve.

Case 1 : In case of EGR solenoid valve open stuck.

EGR solenoid valve is open stuck,

- Engine poor acceleration occurs and engine discharges black smoke, etc…because of excessive EGR gas recirculation.

Replace the EGR solenoid valve.

Case 2 : In case of EGR solenoid valve close stuck.

If EGR solenoid valve is close stuck,

- DTCs of EGR system are displayed and engine discharges excessive NOx, etc... because EGR gas cannot be recirculated.

Replace the EGR solenoid valve.

Case 3 : In case that EGR solenoid valve operation is normal.

If EGR solenoid valve operation is normal,

- MAFS current data is abnormal, go to "MAFS inspection" procedure.