Monitor that "Fuel pressure measured" data should be stable.

Poor power suddenly and poor acceleration above certain rpm at driving could be caused by abnormal fuel system, intake and exhaust system leakage, abnormal EGR system, abnormal VGT system, abnormal CPF system. The purpose of this inspection is to analyze the cause of poor power and poor acceleration.

IG KEY "ON", ENGINE "ON".

Connect scantool to Data Link Connector (DLC).

Allow the engine to warm up to normal operating temperature.

Electrical system and A/CON "OFF".

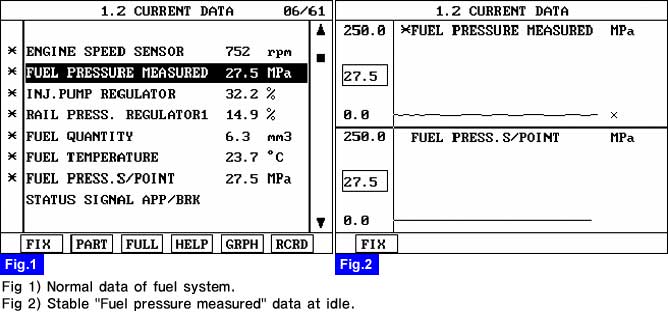

Select "Fuel pressure measured", "Fuel pressure s/point", "Engine speed sensor", "Fuel quantity", "Rail pressure regulator (rail)", "INJ. pump regulator (pump)", "Fuel temperature" parameters on the scantool.

Monitor "Rail pressure regulator (rail)", "INJ. pump regulator (pump)" at 50~70 ℃ fuel temperature, 850 engine rpm.

Monitor that "Fuel pressure s/point" and "Fuel pressure measured" data should be almost same.

Monitor that "Fuel pressure measured" data should be stable.

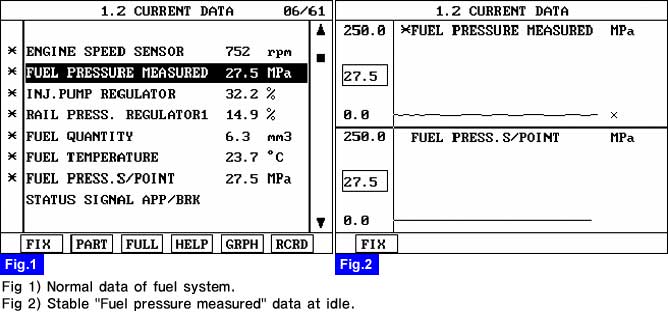

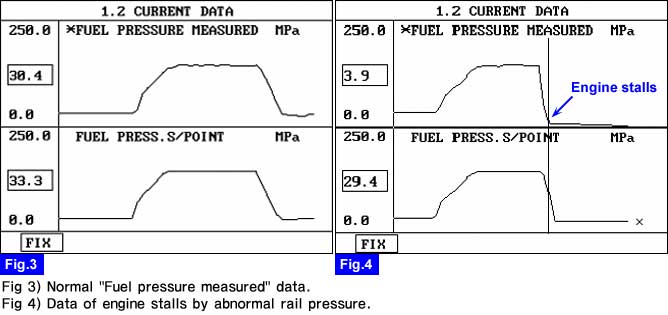

Use graph function after selecting "Fuel pressure measured", "Fuel pressure s/point" and "Engine speed sensor" parameters on the scantool.

Monitor that "Fuel pressure s/point" and "Fuel pressure measured" data should be almost same at stall test.

"Stall Test" of "Details Inspection(Equipment Setting)" reference

Case 1 : In case that fuel system data are normal, "Fuel pressure measured" is controlled by ECM to follow "fuel pressure s/point" normally.

Go to "EGR & MAFS inspection" procedure.

Case 2 :

- In case that "Fuel pressure measured" is unstable or "Rail pressure regulator (rail)" and "INJ. pump regulator (pump)" data is abnormal.

- In case that "Fuel pressure measured" is not controlled by ECM to follow "fuel pressure s/point" at stall test, finally poor acceleration occurs or engine stall.

Go to "Fuel pressure is low inspection" procedure.