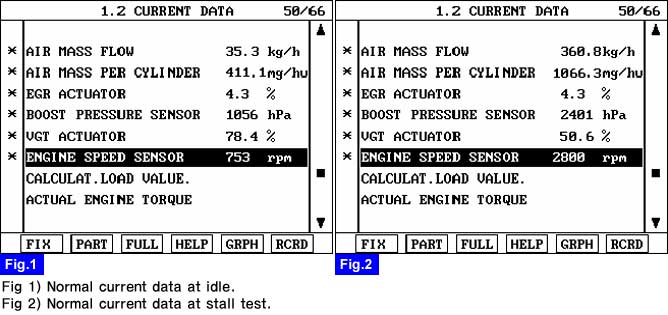

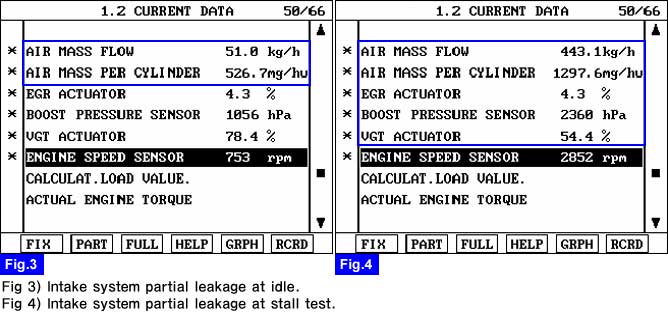

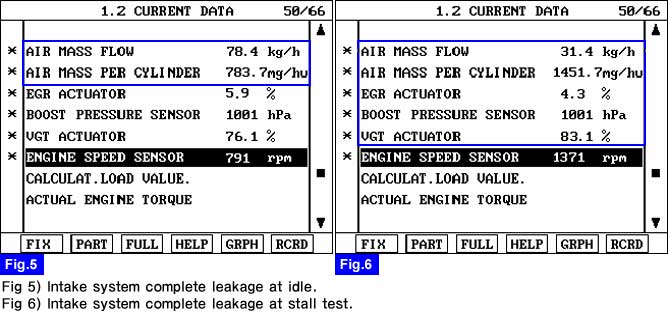

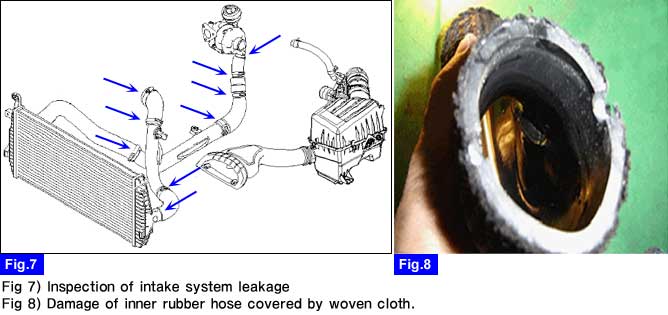

Monitor parameters as above at idle and stall test.

"Stall Test" of "Details Inspection(Equipment Setting)" reference

Monitor current data at idle and stall test : "EGR actuator" is not operated (4.3%)

EGR solenoid valve is operated for approx. 3 minutes after racing the accelerator pedal at warm up idle (Neutral, Load is not applied) and "EGR actuator" duty is to 4.3% after 3 minutes.