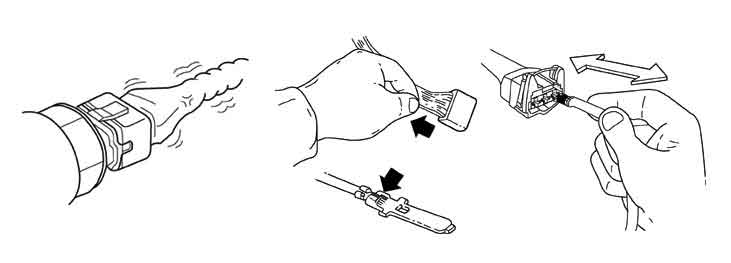

Perform checking procedure as follows.

Check damage of harness and terminals : Check terminals for contact resistance, corrosion and deformation.

Check connecting condition of ECM and component connector : Check terminal seperation, damage of locking device and connecting condition between terminal and wiring.

Disconnect the pin which requires checking at male connector and insert it to the terminal at female connector for checking connecting condition. ( after checking, reconnect the pin at correct position. )