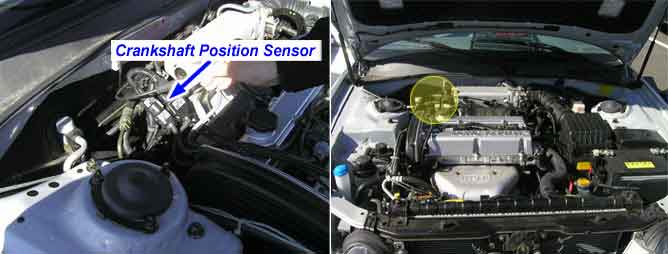

The Crankshaft Position Sensor (CKPS) is a hall effect type sensor that generates voltage using a sensor and a target wheel mounted on the crankshaft. When the slot in the wheel aligns with the sensor, the sensor voltage outputs low. When the metal (tooth) in the wheel aligns with the sensor, the sensor voltage outputs high. The ECM calculates engine RPM by using the sensor’ s signal and controls the injection duration and the ignition timing. The engine will stop if the signals from the sensor to the ECM are lost.

If there is no change of signal, the ECM judged as a fault and DTC is set.

Item | Detecting Condition | Possible Cause |

DTC Strategy | ● Change in output voltage(△Vcrank) is monitored | ● Poor connection ● Open or short in CKPS circuit ● Defective CKPS ● Defective ECM |

Enable Conditions | ● Cranking switch "ON" | |

Threshold value | ● △Vcrank = 0 | |

Diagnostic Time | ● Continuous | |

MIL ON condition | ● 2 driving cycles |

The given data is the normal waveform of the Crankshaft Position Sensor(CKPS) and Camshaft Position Sensor(CMPS) at idle. The ECM controls the injection timing and the ignition timing by using these signals. Generally CKPS signal is used to detect the piston’s position and CMPS signal is used to detect the Top Dead Center of each cylinder.