Monitor parameters on the scantool selected data while engine cranking.

Symptom | Inspection procedure | |

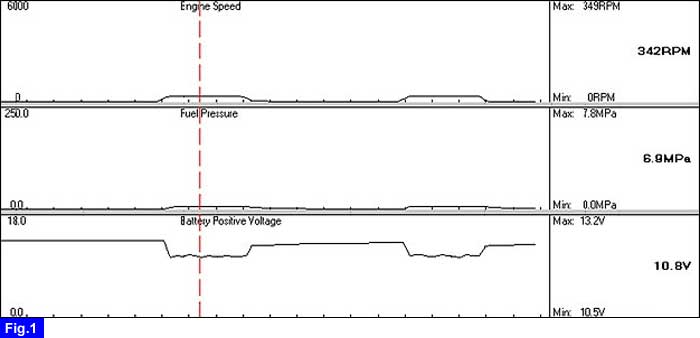

Case1 | ● CKPS and CMPS signals are normal. | ● 'Fuel pressure measured' and 'Engine speed sensor' parameters rise simultaneously while engine cranking but 'Fuel pressure measured' does not rise over 12 Mpa, (Fig1) ☞ Go to 'Fuel system inspection' |

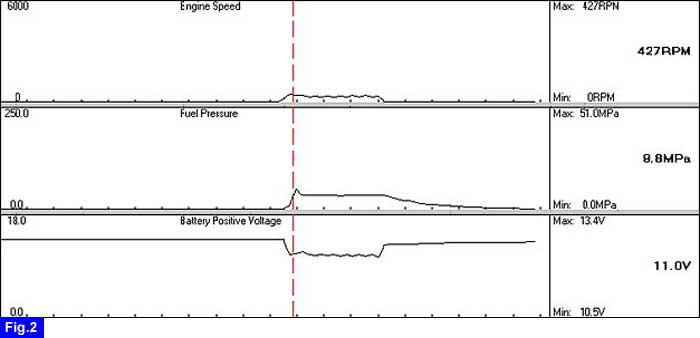

Case2 | ● CMPS signal is abnormal. | ● 'Fuel pressure measured' and 'Engine speed sensor' parameters rise simultaneously while engine cranking but Engine starting is impossible. (Fig 2) ● DTC 'P0341 Camshaft Position Sensor circuit range/performance' would be displayed. caution In case of abnormal fuel system, 'Fuel pressure measured' can not rise. ☞ Go to "CMPS component inspection" |

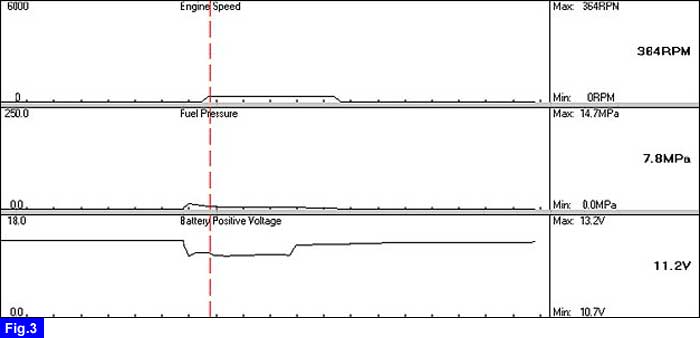

Case3 | ● CKPS signal is abnormal. | ● 'Engine speed sensor' rise after approx. 2~3 seconds after engine cranking. ● 'Fuel pressure measured' does not rise and Engine starting is impossible. ● DTC 'P0335 Crankshaft Position Sensor circuit' would be displayed. (Fig 3) ☞ Go to "CKPS component inspection" |