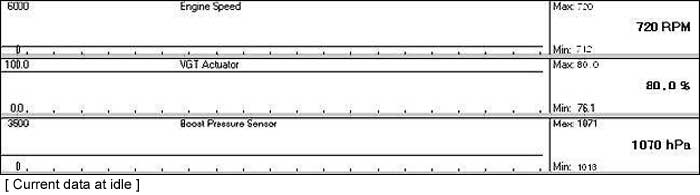

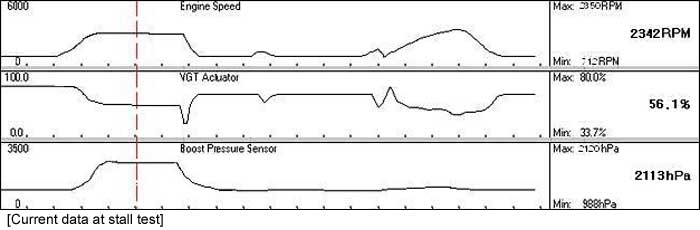

Monitor "Engine speed", "VGT actuator" and "Boost pressure sensor" parameters on the scantool.

☞ Engine speed : Must keep 720 ± 50 rpm at idle.

☞ VGT actuator : Must keep 80 % at idle.

☞ Boost pressure sensor : Must keep atmospheric pressure of present vehicle position (refer to atmospheric pressure current data) ± 100 hPa at idle.