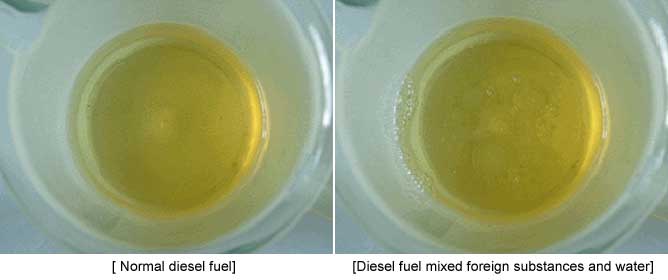

Inspect the diesel fuel (foreign or metallic substances, water etc...from receiving diesel fuel in the beaker).

☞ Metallic substances could be found by magnetic.

Symptom | Inspection procedure | |

Case1 | ● There is a lot of water in the fuel filter. | ● Inspect the poor fuel quality. (Inspect the customer`s gas station.) ● Inspect the damage of the fuel filler whether there is any accident. (If there is damage, water can be input to fuel line by rain, car washing.) ● Repair the fuel filter after cleaning the inside of the fuel tank and fuel line. (If there is a lot of water in the fuel tank.) |

Case2 | ● There is a lot of metallic substances in the fuel filter. | ● Inspect the poor fuel quality by checking the customer"s gas station. (High pressure fuel system would be damaged by poor lubricating performance.) ● Inspect the fuel temperature by checking operation of the FTS (Fuel Temperature Sensor) and Check driver`s driving habit (Vehicle is driven long time continuously or a lot of high load is applied). ● Replace the fuel filter after cleaning the inside of the fuel tank and fuel line. (If there is a lot of metallic substances in the fuel tank.) ☞ Go to "High pressure fuel system inspection" procedure. |