Art the fuel quality, fuel tank and fuel filter normal?

| ▶ Go to "Fuel supply state inspection" procedure as below. |

| ▶ Repair or replace fuel tank and fuel system. |

Before fuel pressure inspection, fuel quality must be inspected first.

Inspect fuel leakage visually from fuel tank and fuel pump mounting point.

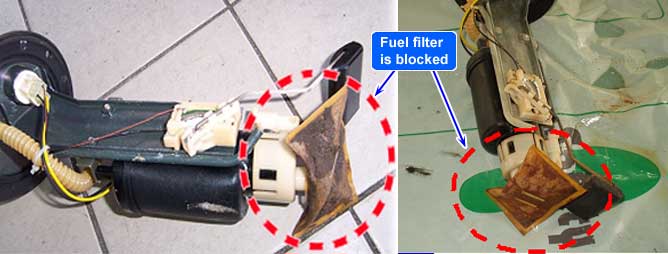

Inspect fuel quality and inside of fuel tank after removing fuel pump.

Check contamination of fuel filter and foreign substances in the fuel filter.

Art the fuel quality, fuel tank and fuel filter normal?

| ▶ Go to "Fuel supply state inspection" procedure as below. |

| ▶ Repair or replace fuel tank and fuel system. |

Toxic odor

Eyes stung

Hard vaporizing

Knocking suddenly after fuelling up

Hard starting after fuelling up (In the winter)

Knocking

Excessive fuel consumption

Poor power/acceleration

Fuel system damage such as fuel pump, Injector and component of the combustion-camber damage such as piston etc...

Deposit rising or corrosion (in the engine and fuel system)

Fuel pressure decrease or Engine stalling by vapor lock.

Impossible starting by low volatile

Discharge carcinogen

Discharge pollutant (CO, HC, NOx etc...)

Measure the fuel pressure at idle after installing a fuel pressure gauge to delivery pipe.

☞ Install a fuel pressure gauge after combustion in the fuel line by removing fuel pump relay.

■ Specification : 324 ~ 363 kPa (3.3 ~ 3.7 kgf/㎠, 46.9 ~ 52.6 psi)

Is fuel pressure within the specification?

| ▶ Go to "Fuel remain pressure inspection" procedure as below. |

| ▶ Repair or replace fuel leakage parts in the fuel filter and fuel hose (whether it is stuck or not). ▶ Replace the fuel pump. |

Monitor fuel pressure at fuel pressure inspection as above.

Engine "STOP"

Check decrease in fuel pressure.

■ Specification : After engine stops, the gage reading should hold for about 5 minutes.

Does the fuel pressure remain after engine stop?

| ▶ Go to "ECTS inspection" procedure. |

| ▶ Replace the fuel pump. (Check valve does not remain pressure.) ▶ Repair or replace fuel leakage parts in the fuel filter and fuel line. |