Connect fuel pump relay power terminal (between terminal '30' and terminal '87', junction box side) directly using jump wire.

First of all check damage of harness and terminals : Check terminals for contact resistance, corrosion and deformation.

Measure operating current to inspect connecting condition of power circuit, operating performance of actuator and motor, ground condition.

IG S/W 'OFF', ENGINE 'OFF'

Remove the fuel pump relay.

Connect fuel pump relay power terminal (between terminal '30' and terminal '87', junction box side) directly using jump wire.

IG S/W 'ON' or ENGINE 'ON'.

Measure the current.

IG S/W 'OFF', ENGINE 'OFF'.

Remove the fuel pump relay.

Select the ampere range (A).

Connect red probe to 10A for measuring current.

Connect multimeter probe to terminal '30' and '87'

IG S/W 'ON' or ENGINE 'ON'.

Measure the current.

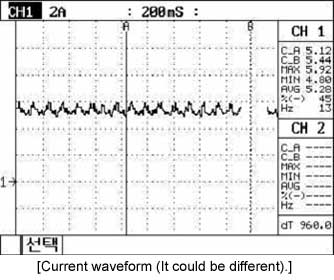

■ Specification : 5.0 ~ 6.0 A (ENGINE 'ON')

☞ Inspect changes of the waveform ( breaking or decreasing current) and current. Approx 5.0 ~ 6.0 A current is flew in a normal vehicle and the regular waveform like blades is displayed by pulsating motion of fuel pump.

Symptom | Inspection procedure | |

Case1 | ● Current is 0 A intermittently, Engine hesitation occurs or engine stalls. | ● Repair open in fuel pump power supply circuit and poor connection of connectors. ● Repair abnormal chassis ground. |

Case2 | ● Current is increased suddenly and fuel pump fuse is blown. | ● Repair short to ground circuit in fuel pump power supply circuit. |

Case3 | ● Current is too low. | ● Repair the high resistance in fuel pump power supply circuit. ● Repair abnormal chassis ground. ● Repair the high resistance in the fuel pump. |

Case4 | ● There is no trouble while measuring the current. | ● Go to 'Fuel pump relay inspection' |