Measure waveform of terminal '1' of Boost pressure sensor connector by using oscilloscope.(Do not disconnect)

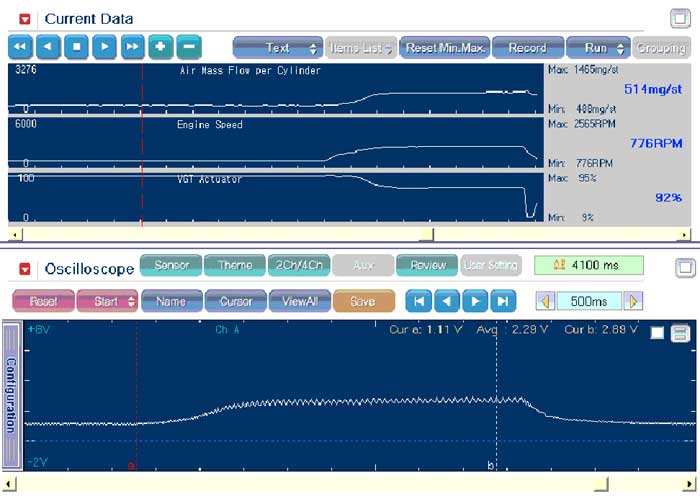

☞ Engine speed : Must keep 770 ± 50 rpm at idle.

☞ VGT actuator : Must keep 92 % at idle.

☞ Boost pressure sensor : Must be approx 1.1V at idle (Measuring by using oscilloscope )

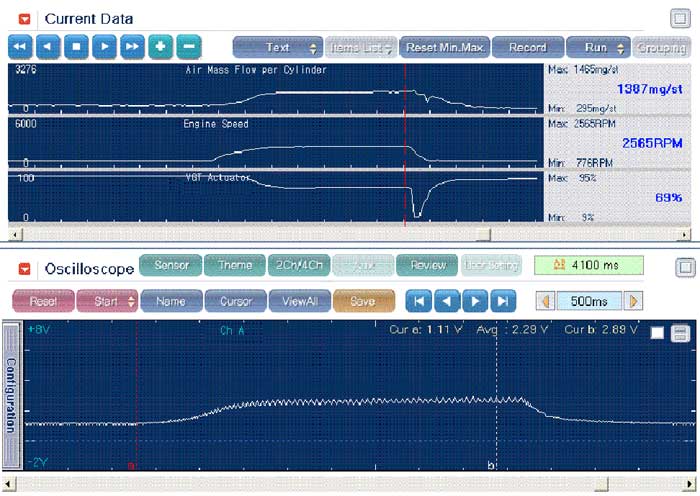

[ Current data at idle ]