Install hand vacuum pump to the VGT vacuum actuator nipple.

In case of low or high boost pressure, Inspect variable vane of the VGT (Variable Geometry Turbocharger) whether it is stuck or not.

IG KEY "OFF", ENGINE "OFF"

Disconnect VGT vacuum actuator hose.

Install hand vacuum pump to the VGT vacuum actuator nipple.

Inspect rod stroke of VGT while vacuuming with hand vacuum pump to VGT vacuum actuator. (Inspect rod stroke of VGT visually by using pocket mirror.)

☞ When -65 kpa vacuum is supplied by hand vacuum pump, rod of VGT must be moved to up stopper.

☞ On the contrary when vacuum is released, rod of VGT must be moved to down stopper softly. (Rod stroke of VGT stroke is approx. 10 mm.)

[ Rod of VGT ]

Symptom | Inspection procedure | |

Case1 | ● In case of leakage from VGT vacuum actuator. | ● Replace VGT assembly. (VGT vacuum actuator diaphragm is damaged.) |

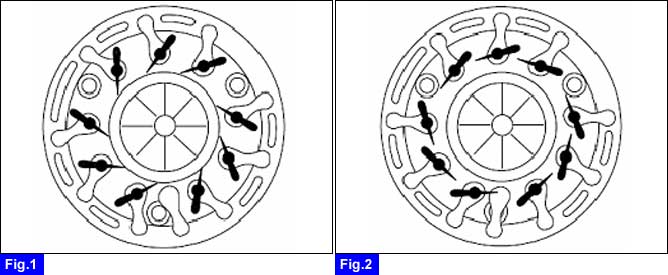

Case2 | ● In case that rod of VGT is not moved to upside. (A lot of exhaust gas can passes through vane because cross sectional area between vanes is wide. Vane connected by unison ring could not be moved because unison ring is stuck.) | ● Generally poor power occurs and poor acceleration occurs at low rpm remarkably. ● Replace VGT assembly. (Refer to Fig1) |

Case3 | ● In case that rod of VGT is stuck on upside. (Exhaust gas can not passes through vane well because cross sectional area between vanes is small. Vane connected by unison ring could not be moved because unison ring is stuck.) | ● Engine could not be accelerated above 3,000 rpm because fuel quantity is limited by excessive boost pressure. ● If vehicle is driven a long time at this condition, Impeller of turbocharger could be damaged. ● Replace VGT assembly. (Refer to Fig2) |