Monitor 'Fuel pressure' data on the GDS(scantool).

☞ Fuel pressure : 0 ~ 3.0 Mpa

If RPS(Rail Pressure Sensor) senses more higher pressure than actual rail pressure because of RPS malfunction, Common rail pressure is lower than rail pressure SET point.

RPS malfunction affects fuel injection quantity. Therefore, Poor power occurs and ECM increases fuel injection quantity for compensating insufficient toque because actual fuel injection quantity is smaller than fuel injection quantity SET point controlled by ECM.

There are no worn high pressure pump, no leakage of rail pressure regulator (rail), no blocked fuel pressure regulator (pump), no decreasing fuel injection quantity of injector. But If fuel injection quantity is bigger than normal condition, Inspect RPS performance after checking fuel system.

If RPS(Rail Pressure Sensor) senses more lower pressure than actual rail pressure because of RPS malfunction, Common rail pressure is higher than rail pressure SET point. Therefore accelerating performance is high, but black smoke and knocking noise (combustion sound) occur.

IG KEY "ON", ENGINE "ON"

Connect GDS(scantool) to Data Link Connector (DLC).

Allow the engine to warm up to normal operating temperature.

Electrical system and A/CON "OFF".

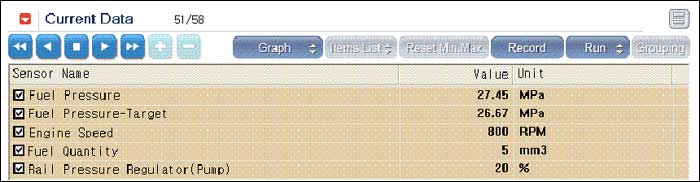

Select 'Fuel pressure', 'Fuel pressure-Target', 'Rail pressure regulator (pump)'parameters on the GDS(scantool).

IG KEY "OFF", ENGINE "OFF"

Wait around 15 seconds until Main relay 'OFF'

☞ If Main relay is not 'OFF' normally, fuel pressure is not '0.0' Mpa.

IG KEY "ON"

Monitor 'Fuel pressure' data on the GDS(scantool).

☞ Fuel pressure : 0 ~ 3.0 Mpa

IG KEY "ON", ENGINE "ON"

Monitor 'Fuel pressure' data on the scantool at idle (Load is not applied).

☞ Fuel pressure : Must be 27~28 Mpa and be same with 'Fuel pressure-Target'

☞ Fuel pressure regulator (pump) : Must be 18~22%

☞ Fuel quantity : Must be 4.0~6.4㎣

Symptom | Inspection procedure | |

Case1 | ● 'Fuel pressure' is above 5 bar(0.5MPa) at IG KEY 'ON' after common rail pressure is released. | ● Replace RPS (common rail assembly). |

Case2 | ● 'Fuel quantity' is above 6.0 ㎣ at idle (Load is not applied) and poor acceleration occurs. | ● Worn high pressure pump (high pressure pump performance is getting worse) ● Blocked fuel pressure regulator (pump) ● Decreasing fuel injection quantity of injector. ● Repair RPS (common rail assembly) after checking as above. |

Case3 | ● 'Fuel quantity' is under 4.0 ㎣ at idle (Load is not applied) with black smoke, knocking noise (combustion noise). | ● Replace RPS (common rail assembly). |